Factory Automation

Abhison Innovations Pvt Ltd specializes in delivering advanced factory automation solutions that streamline operations and improve productivity. From pick & place automation and gantry systems to palletizing, conveyor automation, Rotary Table Automation,and special-purpose machines, our solutions are designed to meet the unique demands of modern manufacturing environments. With a focus on precision and reliability, our automation systems optimize workflow, reduce manual intervention, and increase overall efficiency, ensuring your factory operates at peak performance.

Pick & Place Automation

Abhison's Pick & Place Automation systems are engineered to enhance manufacturing efficiency through precise and reliable material handling. Designed for seamless integration into factory production lines, these systems automate the picking and placing of components, reducing manual labor and increasing throughput. Our solutions ensure accurate placement and movement, optimizing workflow and minimizing errors, making them essential for factories looking to boost productivity and maintain high standards of quality.

Gantry Automation

Abhison's Gantry Automation systems are designed to deliver precise, automated handling for complex manufacturing tasks. Ideal for heavy-duty and large-scale operations, our gantry systems provide accurate and efficient movement of materials across multiple axes, ensuring smooth and reliable performance. By automating these processes, we help factories increase productivity, reduce manual intervention, and maintain high levels of precision and consistency throughout their operations.

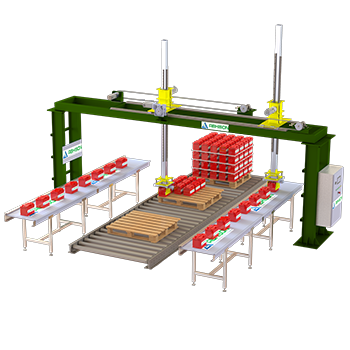

Palletizing and Depalletizing systems Automation

Abhison's Palletizing and Depalletizing Systems Automation is designed to optimize material handling processes in manufacturing environments. These systems efficiently automate the stacking and unstacking of products on pallets, reducing manual labor and increasing throughput. By ensuring precise and consistent handling of materials, our systems enhance operational efficiency, minimize errors, and support high-volume production needs. Ideal for industries that require reliable and scalable automation, our solutions are key to maintaining smooth and efficient workflows.

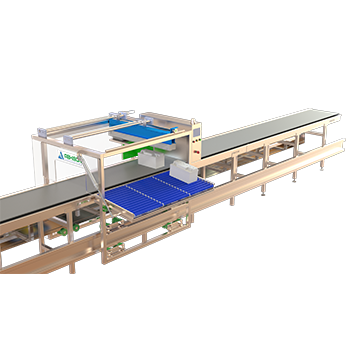

Conveyor Automation

Abhison's Conveyor Automation systems are engineered to streamline the movement of materials across production lines, optimizing workflow and reducing manual handling. Our automated conveyors ensure smooth, continuous transport of goods, improving productivity and minimizing downtime. Designed for flexibility and reliability, these systems can be customized to fit a wide range of factory layouts and production needs. By automating material flow, our conveyor solutions contribute to more efficient, safe, and scalable manufacturing processes.

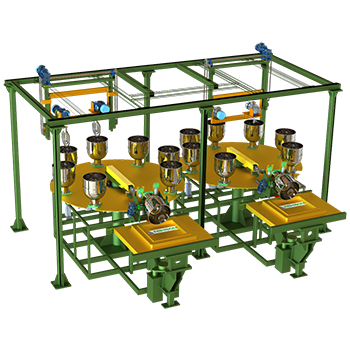

Special Purpose Machine Automations

Abhison specializes in designing and implementing Special Purpose Machine Automations to address the unique challenges of specific manufacturing processes. These custom-built machines are engineered to perform specialized tasks with high precision and efficiency, integrating seamlessly into existing production lines. Whether you need to automate a complex process or enhance a particular operation, our tailored solutions optimize performance, reduce manual intervention, and ensure consistent quality, helping you achieve your production goals with greater accuracy and reliability.

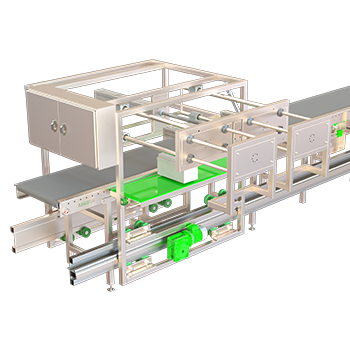

Indexing

Abhison's Indexing Automation systems are designed to provide precise control and positioning of components in manufacturing processes. Our indexing solutions ensure that parts are accurately aligned and positioned for subsequent operations, enhancing the overall efficiency and consistency of production lines. With reliable performance and seamless integration, these systems are ideal for applications requiring high-speed, repeatable accuracy, making them a crucial component of any automated manufacturing setup.

Rotary Table Automation

Abhison's Rotary Table Automation systems are engineered to optimize multi-station processes with precision and efficiency. The rotary tables enable controlled, sequential movement between various production stations, ensuring smooth transitions and consistent quality. Ideal for applications requiring repetitive, high-precision tasks, these systems reduce cycle times and enhance overall workflow. Built with robust components and designed for reliability, our rotary table automation solutions are essential for maximizing productivity in complex manufacturing environments.