Battery Manufacturing Equipment

At Abhison Innovations Pvt Ltd, we are at the forefront of delivering advanced solutions for the battery industry. As pioneers in SPM and battery equipment manufacturing, we provide a full range of services, from standalone products to complete turnkey projects. Our expertise covers a wide spectrum of battery types, including Inverter, Solar, Automotive, Tubular, and Gel, ensuring that we meet the diverse demands of the market with precision and excellence.From initial design and development to manufacturing, installation, and commissioning, we offer end-to- end solutions that not only streamline your operations but also enhance efficiency and productivity. Whether you need equipment for a specific battery type or a comprehensive setup for a large-scale production facility, our cutting-edge technology and industry expertise guarantee reliable, high- performance outcomes that drive your success.

Casting :

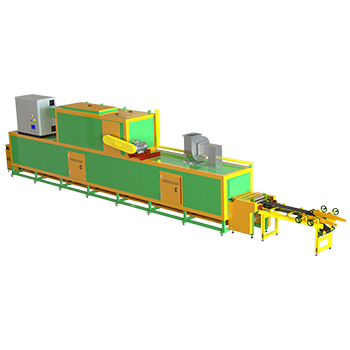

Grid Aging Oven

Our Grid Aging Ovens are essential for hardening and strengthening the grids of battery plates, as well as lead strips for expanded and punched grids. These specialized ovens provide a controlled environment for heat treatment, ensuring the microstructure age hardening of ASG coils coiled in spools. By precisely managing heat and time, our Grid Aging Ovens enhance the durability and performance of battery components, making them an integral part of high-quality battery manufacturing processes.

Mixing & Pasting :

Curing Oven

Designed with a deep understanding of the complexities of the curing process, Abhison Curing Chambers are engineered to provide precise control over this critical step in lead-acid battery manufacturing. The curing process is essential for forming the correct crystalline structures within the battery plates, which directly influence the battery's performance, longevity, and efficiency. Our curing chambers offer advanced control over temperature and humidity, ensuring that the optimal ratio of tri-basic (3BS) and tetra-basic (4BS) lead sulphate crystals is achieved. This balance is crucial for the battery’s ability to meet specific application requirements. By maintaining uniform conditions throughout the curing process, our chambers ensure that the active material in the battery plates is properly hardened, leading to superior durability and performance. Equipped to meet the highest standards of quality, our chambers ensure that your batteries deliver consistent and reliable power across all applications.

Flash Drying Oven

At Abhison, our Flash Drying Ovens (FDOs) are engineered to deliver exceptional uniformity in plate drying, a vital process in battery manufacturing. With advanced control systems, our FDOs ensure that each plate is dried consistently and thoroughly, minimizing defects and maximizing battery performance. What sets our ovens apart is their superior energy efficiency, which reduces operational costs without compromising productivity. For manufacturers who demand precision and reliability, Abhison FDOs provide an optimal solution for high-quality, cost-effective plate drying.

Assembly :

COS

Abhison offers Cast-On-Strap (COS) Machines that deliver unmatched precision and efficiency in battery plate assembly. Our advanced automation ensures strong, uniform connections at high speeds, enhancing battery performance and longevity. With user-friendly controls, energy-efficient operation, and robust construction for long-term reliability, our COS machines integrate seamlessly into any production line. Customized to meet your specific needs, and backed by comprehensive support, Abhison’s COS machines set the standard for excellence in battery manufacturing.

Short Circuit Tester

Abhison's Short Circuit Tester ensures the safety and reliability of your battery production. Designed for seamless integration into assembly lines, our tester quickly identifies potential short circuits, preventing defects and ensuring consistent quality. With fast, accurate testing and robust construction, it’s an essential tool for maintaining high safety standards and optimal battery performance.

Weld Quality Tester

Abhison's Weld Quality Tester is designed to verify the strength and integrity of welds in battery assembly lines. By providing quick and accurate assessments, our tester ensures that every weld meets the highest standards, preventing potential failures and enhancing the overall durability of your batteries. Seamlessly integrated into your production line, it’s essential for maintaining quality and reliability in battery manufacturing.

Air Leak Tester

Abhison's Air Leak Tester is essential for ensuring the airtight integrity of batteries during assembly. Our tester quickly detects any potential leaks, guaranteeing that each battery meets stringent sealing standards. By preventing defects and ensuring reliability, the Air Leak Tester is crucial for maintaining the quality and performance of your battery product

Battery Charging Section :

Acid Filling Machine

Abhison's Acid Filling Machine delivers exceptional precision and efficiency in battery production. With fine level control in each cell and automatic level setting in recipes, this machine is designed for zero leakage and maintenance-free operation. Its energy-efficient design and long-life sensors ensure reliable, long-term performance. Ergonomically designed for ease of use, it’s the perfect solution for maximizing productivity and ensuring top-tier battery quality

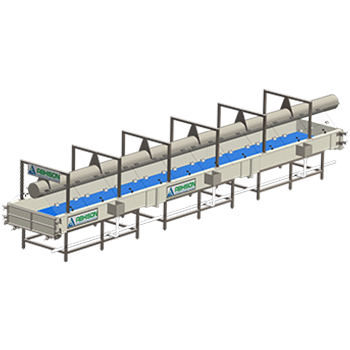

Charging Tubs with Fume Extraction System

Abhison's Charging Tubs with Fume Extraction System are designed to enhance safety and efficiency during the battery charging process. These tubs are equipped with an advanced fume extraction system that effectively removes hazardous gases, ensuring a safer working environment for operators. The robust design of the charging tubs ensures durability and reliable performance, while the integrated fume extraction system minimizes environmental impact and improves air quality. Ideal for large-scale battery production, our solution ensures compliance with safety standards while maintaining high operational efficiency.

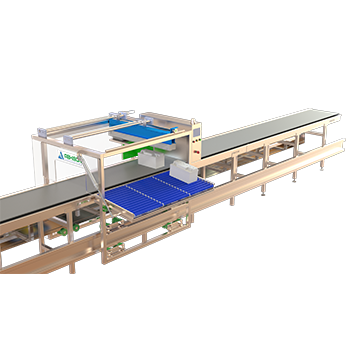

Loading & Unloading Shuttle

Abhison's Loading & Unloading Shuttle is designed to automate the handling of batteries in and out of tubs, streamlining your production process. This advanced shuttle system ensures precise and efficient movement, reducing manual intervention and minimizing the risk of damage during transfer. With robust construction and seamless integration into your production line, our shuttle enhances operational efficiency and supports high-volume battery manufacturing. Ideal for improving workflow and reducing labor costs, the Loading & Unloading Shuttle is an essential component for any modern battery production facility.

Finishing Line :

Acid Re-Fillling and Levelling Machine

Abhison’s Fully Automatic Acid Re-Filling & Leveling Machine incorporates sensor-based technology with an individual Cell Level Control System. This advanced system guarantees precise acid levels, completely eliminating the risk of overflow or spillage. Additionally, it offers fine control over vacuum levels, significantly reducing air consumption while promoting efficiency and sustainability. Designed for reliability and precision, this machine ensures consistent quality in battery production, making it an indispensable tool in your manufacturing process.

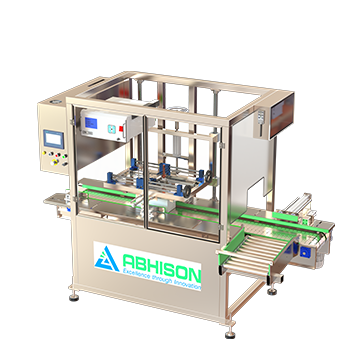

Battery Washing and Drying Machine

Achieve pristine cleaning and 100% dryness with Abhison's Fully Automatic Battery Washing and Drying Machine. Designed for maximum efficiency, this machine features an integrated pH dosing system that ensures optimal washing conditions. Your batteries deserve the best care, and our machine delivers excellence every time, ensuring they are thoroughly cleaned and perfectly dried, ready for the next step in your production process.

Production Line Tester with HRD

Abhison's Fully Automatic Production Line Tester with HRD is designed to enhance productivity and ensure the highest standards of quality in battery manufacturing. With its energy-efficient design, this tester minimizes power consumption, reducing environmental impact while optimizing production processes. By improving overall productivity and contributing to sustainable manufacturing practices through efficient resource utilization, our Production Line Tester is an essential tool for modern battery production facilities.

High Voltage Leak Testing Machine

Abhison's High Voltage Leak Testing Machine is designed for accurate and reliable detection of pinholes in battery containers and lids. With a high voltage testing capability of up to 12 KV, this machine ensures thorough inspection at critical points, including the injection point at the bottom of the container. Engineered for precision, it guarantees accurate leak detection, enhancing the quality and safety of your battery products.

Acid Level Checking Machine

Abhison's Acid Level Checking Machine is designed to address the critical challenge of maintaining consistent electrolyte levels in battery cells. This state-of-the-art equipment precisely measures electrolyte levels in each cell, ensuring optimal battery performance. Equipped with advanced technology, it records data in real-time and automatically rejects any batteries with levels outside the specified range. Developed to operate at high speeds, this machine enhances efficiency and accuracy in battery manufacturing, ensuring reliability in every batch.